IR Aerials

We've changed our name. We're now Structura View.

About Structura View

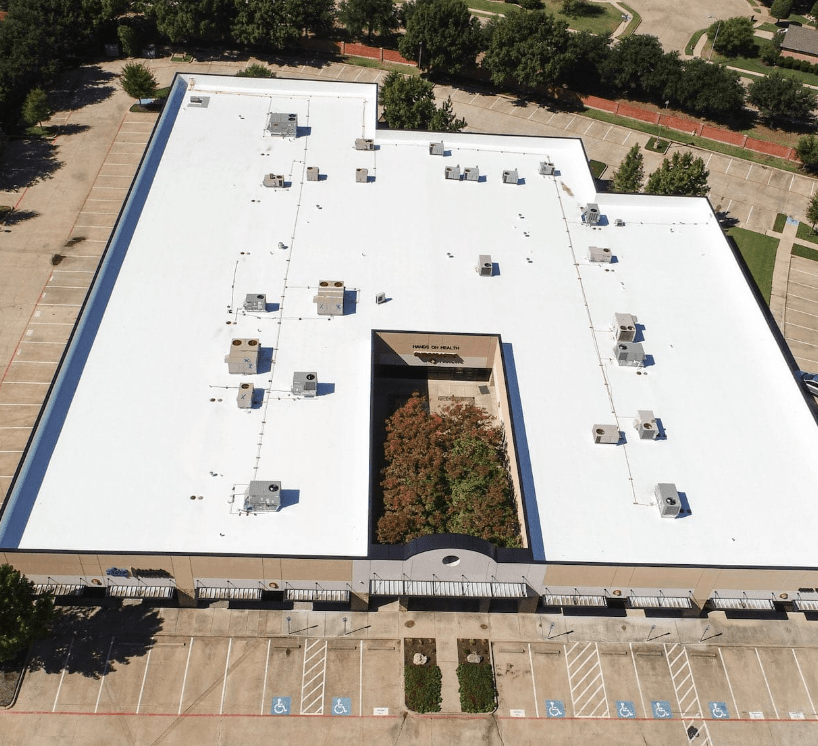

Structura View is a full-service roof consulting agency helping commercial property owners and other industry professionals manage and extend the life of their buildings. We provide drone inspections, moisture testing, reporting, consulting, and more.

Our History

2020

Initial Launch of IR Aerials

Full service roof inspection service is launched targeting inspections with drone thermal

and visual imagery.

2021

Service Regions Expanded

Roof & building facade investigations expand to North Pacific, Southeast, and Midwest.

2022

Services Offerings Expanded

Consulting Services & Quality Assurance Programs

are added.

2023

Then Came Structura View

Structura View rebrands as a full service roof consulting agency.

View our expanded capabilities and clients: